Building a blockbuster

Taking a molecule all the way from the laboratory to the farmer’s field.

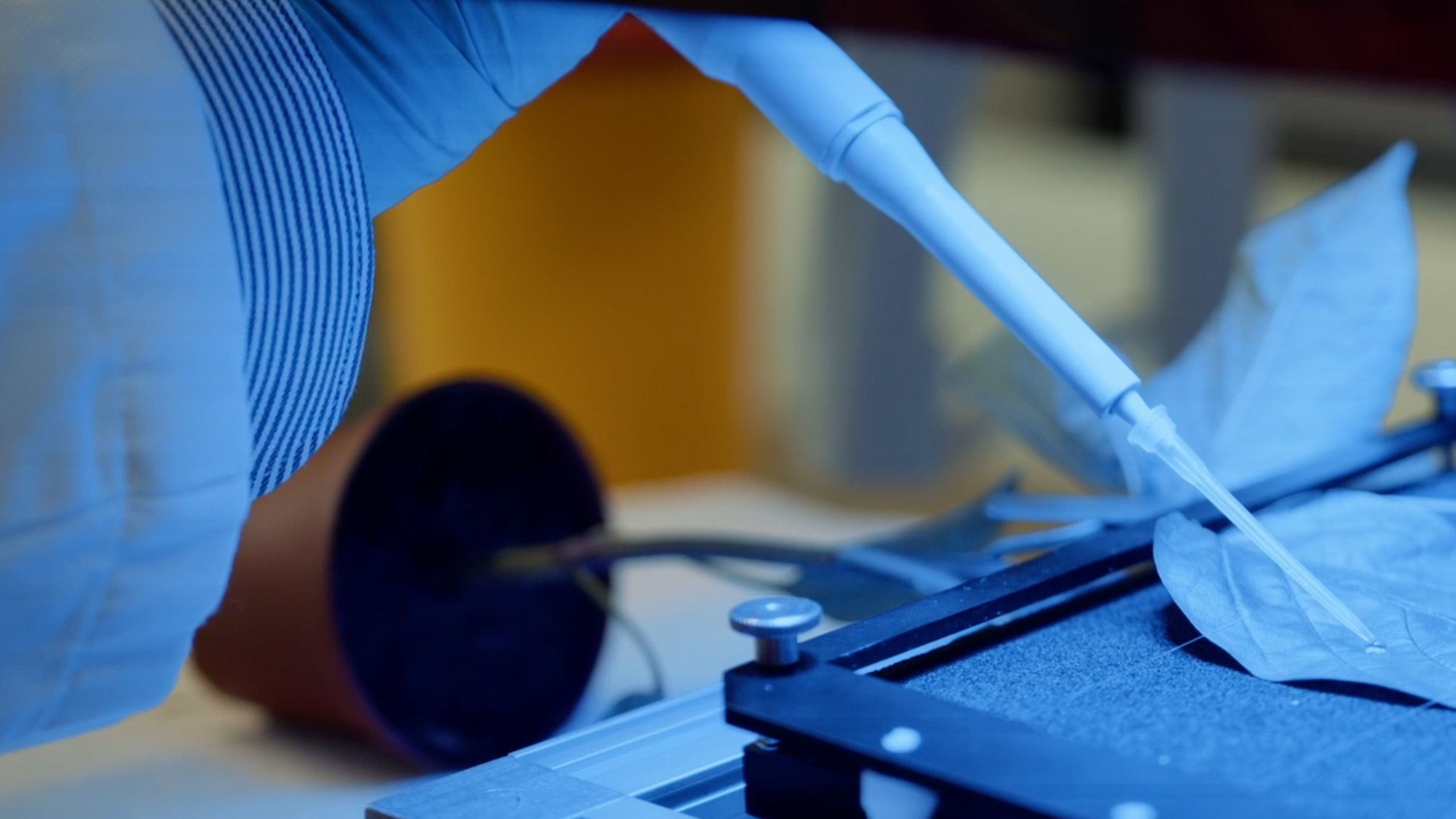

When it comes to developing a new crop protection tool for farmers, everything starts with a single molecule. Through rigorous cycles of designing, testing and refining, a promising candidate emerges in the laboratory. From there, it’s on to stringent tests, including in the field, to make sure this new chemical is up to the job of tackling disease, and that it meets the highest possible safety standards.

A molecule might sail through these early challenges with flying colors, but next comes a new set of scientific and logistical challenges. How do you go from a molecule that might only exist in small amounts in a lab, to a cost-effective product that can be produced safely, sustainably and in enough volume to meet urgent needs across the planet?

It was this challenge that the team behind the development of ADEPIDYN® technology had to solve. Products containing ADEPIDYN® technology have, over the last decade, gone on to become blockbusters – safe, efficacious and broad-spectrum fungicides that are used on multiple different crops around the world.

But to get it from the lab to the field required a team of development and technical experts whose goal was to work out how to scale up production from a few grams to hundreds of tons.

Much of this work took place at Münchwilen, Syngenta’s leading development site in Switzerland - where chemicals are scaled up and processes that turn an idea into a product kick into gear. Think of it as the bridge connecting the R and D in R&D, from the lab where an idea takes shape, to the production sites which make the products for farmers.

The team who expertly guided ADEPIDYN® technology through development to its first production campaign, was awarded the prestigious Syngenta Science and Technology Prize.

Gregori Binot (Senior Process Chemist), Ralf Kohlbrenner (Process Technology Laborant) and Alexandre Saint-Dizier (Senior Plant Assistant) were all part of that prize-winning team.

The winning team of (left to right) Gregori Binot, Jose-Luis Calvo, Nicolas Fedou, Ralf Kohlbrenner, Christian Mink, Alexandre Saint-Dizier accepting the award.

The winning team of (left to right) Gregori Binot, Jose-Luis Calvo, Nicolas Fedou, Ralf Kohlbrenner, Christian Mink, Alexandre Saint-Dizier accepting the award.

This year, Syngenta is celebrating its 25th anniversary. Check out more of our stories about innovation.

This year, Syngenta is celebrating its 25th anniversary.

What is the Syngenta Science & Technology Prize?

Syngenta recognizes our scientists' achievements and celebrates the breakthroughs that emerge from their work through the Science and Technology (S&T) Prize. Investing in exceptional talent and celebrating innovation is one of the reasons we are known as a top five science employer.

With decades of combined experience in developing new products and refining processes to make something work at scale, the trio are quick to point out that it’s impossible to count the number of people who actually worked on the new product.

Kohlbrenner says: “It was easily hundreds of people who were involved – this is one of the reasons why only companies like Syngenta can bring new active ingredients to market. You need so much investment, and so many people across technical, regulatory and scientific fields all working together.”

Saint-Dizier adds: “That’s not even counting what happens when you move into production. People need to do studies to say, ‘yes, we think we can do that’. But you might have to change the equipment at a production site or buy new equipment. Then you must get the knowledge of the process from Münchwilen where the product was developed, to the site that will actually be making the large volumes of product.”

And those volumes are impressive – in the development process the amounts needed go from a liter for early experiments, to around 1,500 liters in pilot production. Some Syngenta plants can produce as much as 60,000 liters of products and it is teams like this that help make that a reality. But, when you move from lab conditions to the challenges of manufacturing at scale, new problems can quickly emerge.

The complexity of the chemistry involved means that experience and expertise are essential for solving those problems when they arise. For example, Kohlbrenner points out that he had been working for Syngenta and legacy companies for 30 years. And, as a result, when ADEPIDYN® technology production was struggling with yield volumes and concentrations, he drew on that knowledge to help find a solution.

He says: “I had worked on a project for one of our legacy companies and used that knowledge to help the process for ADEPIDYN® technology. The timeframe was very short, so we ended up combining two steps of the production process and that helped to solve the volume issues and make things more cost effective.”

Saint-Dizier says: “Ralf’s work helped solve a lot of the early problems around efficacy, safety and cost.” But forming and synthesizing an active ingredient is often a multi-stage series of chemical interactions – and so the whole process is broken down into blocks that would feature one or two chemical interactions at a time.

As Saint-Dizier explains: “My work focused on a stage which needed to use platinum as a catalyst – this is very expensive, so we needed to find a way of using the least amount of platinum possible to get the reaction we needed to maintain efficacy.”

Solving these scientific challenges then raises new questions that have to be solved.

Binot says: “I was involved at a later stage in the development process when we moved from the laboratory to larger scale production at our Monthey site. We needed to make more than had originally been forecasted too. When you develop for production, you need to make a high-volume at low costs, so we have to adapt and even deviate a little from previous processes developed in the laboratory.”

One of the most important things that Binot emphasizes is the iterative nature of the entire process. “We would encounter a problem and go back to reports or experiments done by teams at previous stages and find possible answers there.”

Join a tour behind the scenes and get to know our colleagues from plants across the country who reveal how innovation is at the heart of what we do to solve agriculture’s challenges of today and tomorrow.

Saint-Dizier adds: “This collaboration is so important as there are so many people around the world that need to work together to help get a product through development.”

Innovations such as ADEPIDYN® technology don’t just depend upon a small team of brilliant scientists but a complex network of people from around the world. And, as the last decade has proven, it is farmers everywhere who benefit from this network, as their work delivers the blockbuster products which protect crops and help guarantee our food security.

This year, Syngenta is celebrating its 25th anniversary. We are proud of our continuous innovation and contribution to the food system over the past quarter century. Check out more of our stories about innovation.

This year, Syngenta is celebrating its 25th anniversary. We are proud of our continuous innovation and contribution to the food system over the past quarter century. Check out more of our stories about innovation.