A breakthrough 100 years in the making

Accessible solutions for storing maize pollen? Solved at Syngenta.

For more than a century, maize scientists have struggled with a fundamental agricultural challenge: how to reliably store and keep pollen viable at the scale needed for hybrid seed production.

Now, Syngenta researchers have pioneered a solution, opening new possibilities for plant breeding worldwide.

Delicate nature of life

For farmers everywhere, pollination is a vital step in the life cycle of a crop. To put it simply, without pollination there is no harvest. Pollen is key to the global food production system.

For Syngenta, improving the crops that the world depends on means it's vital to find ways of working with pollen. Cross-pollination can produce new hybrids with better yield and stronger disease resistance. This has been a foundational part of plant breeding since the days of Gregor Mendel, who cross pollinated his pea plants in a monastery garden with a paintbrush.

The problem? Pollen is fragile: depending on the species it can last from a matter of days to – in some cases – only a few minutes. Leave it for too long and the pollen will be dried out and desiccated.

Take corn for example. Corn pollen typically survives just hours under normal conditions. If you want to make hybrids, then you need male and female plants to flower at the same time. Storing pollen means it’s likely to form clumps and if that happens it’ll die quickly. Traditional approaches, such as storing pollen in sealed vessels at low temperatures, extend viability to roughly three days. More advanced methods like cryogenic freezing help but are difficult to scale.

“This isn’t a new problem – research shows that pollen storage has been a scientific and technical challenge for the last century, but it’s one we’ve now been able to solve,” says Jared Carter, Principal Scientist, R&D Trait Technologies and Genome Editing Traits.

Jared Carter, Principal Scientist, R&D Trait Technologies and Genome Editing Traits

Jared Carter, Principal Scientist, R&D Trait Technologies and Genome Editing Traits

“Freezing might extend pollen viability, but it’s a technology with drawbacks – if the moisture content is too high the pollen will be damaged by the process,” explains Carter.

Rethinking the Basic Needs of Life

The global team’s breakthrough, recently published in Nature journal’s Communications Biology, began with a fundamental shift in perspective.

“How we view plants impacts the choices we make as scientists,” explains Carter. “If we think of pollen as a durable organism, we might think freezing is the best way to handle the problem, but what if we think of pollen as a living creature instead?”

Thinking of pollen as alive means that it has the same basic needs as all living creatures: food, water, shelter and air to breathe. Their research revealed that pollen stored in airtight containers essentially suffocates under accumulated CO₂. Similarly, temperatures that are too low don't preserve pollen — they kill it.

“You have to let pollen breathe, so we started out testing breathable barriers for storage vessels, and finding ways of keeping CO₂ levels under control,” says Carter. Through careful testing, the team developed an optimized, breathable barrier for pollen storage.

This crucial understanding led Carter’s team of scientists to pioneer a pollen storage solution that allows pollen to be safely stored for as long as seven days, something that was previously considered impossible at production scale.

For this work, Carter received the Syngenta Science and Technology Prize, awarded annually to recognize transformative breakthroughs in plant sciences.

But innovations don’t mean much if they don’t work in the field, so the team’s research has gone through extensive worldwide field trialling across multiple climates.

After settling on a design for a storage vessel that was breathable for the pollen, the team put it to the test. “Our big breakthrough came when we successfully collected one liter of pollen. That’s one billion live pollen grains!” Carter says.

With their focus on scalability, the team moved from collecting a liter of pollen at one test site to being able to collect and store a colossal 48 liters — or a massive 48 billion grains of viable pollen.

Corn is a key crop and the pollen is vital for producing new hybrids.

Corn is a key crop and the pollen is vital for producing new hybrids.

Rethinking the Basic Needs of Life

The global team’s breakthrough, recently published in Nature journal’s Communications Biology, began with a fundamental shift in perspective.

Corn is a key crop and the pollen is vital for producing new hybrids.

Corn is a key crop and the pollen is vital for producing new hybrids.

“How we view plants impacts the choices we make as scientists,” explains Carter. “If we think of pollen as a durable organism, we might think freezing is the best way to handle the problem, but what if we think of pollen as a living creature instead?”

Thinking of pollen as alive means that it has the same basic needs as all living creatures: food, water, shelter and air to breathe. Their research revealed that pollen stored in airtight containers essentially suffocates under accumulated CO₂. Similarly, temperatures that are too low don't preserve pollen — they kill it.

“You have to let pollen breathe, so we started out testing breathable barriers for storage vessels, and finding ways of keeping CO₂ levels under control,” says Carter. Through careful testing, the team developed an optimized, breathable barrier for pollen storage.

This crucial understanding led Carter’s team of scientists to pioneer a pollen storage solution that allows pollen to be safely stored for as long as seven days, something that was previously considered impossible at production scale.

For this work, Carter received the Syngenta Science and Technology Prize, awarded annually to recognize transformative breakthroughs in plant sciences.

But innovations don’t mean much if they don’t work in the field, so the team’s research has gone through extensive worldwide field trialling across multiple climates.

After settling on a design for a storage vessel that was breathable for the pollen, the team put it to the test. “Our big breakthrough came when we successfully collected one liter of pollen. That’s one billion live pollen grains!” Carter says.

With their focus on scalability, the team moved from collecting a liter of pollen at one test site to being able to collect and store a colossal 48 liters — or a massive 48 billion grains of viable pollen.

The Carrier Compound Conundrum

But storage is only half the battle. For effective pollination, stored pollen needs a carrier material that prevents clumping while allowing pollen to bind with plant silks.

The industry standards — talcum powder and amorphous silicas — prevented clumping but excessively coated pollen grains, reducing successful pollination rates. The team initially found success with crystalline silica but had concerns about respiratory hazards and global availability.

The team’s solution? Microcrystalline Cellulose (MCC), a refined wood pulp that looks like a fine white powder. “It’s sustainable, biodegradable, and much safer than silica,” explains Carter. MCC doesn’t coat pollen in the same way and still manages to keep the pollen from clumping together.

This breakthrough exemplifies Syngenta’s core approach: bold discovery leading to better benefits at bigger scale. This kind of accessible science is essential to develop higher yielding hybrid corn in a more sustainable way. As climate challenges mount and food security concerns grow, innovations like this demonstrate how Syngenta empowers farmers to meet the dual challenge of producing more food while preserving our planet.

“What’s most exciting about this new protocol is its scalability and its simplicity,” Carter says. “We’ve tested this across the world, and we’ve found it works with tropical and temperate corn, using equipment that’s easy to get in the field and pollen stored with our protocol can achieve equivalent results to fresh pollen too.”

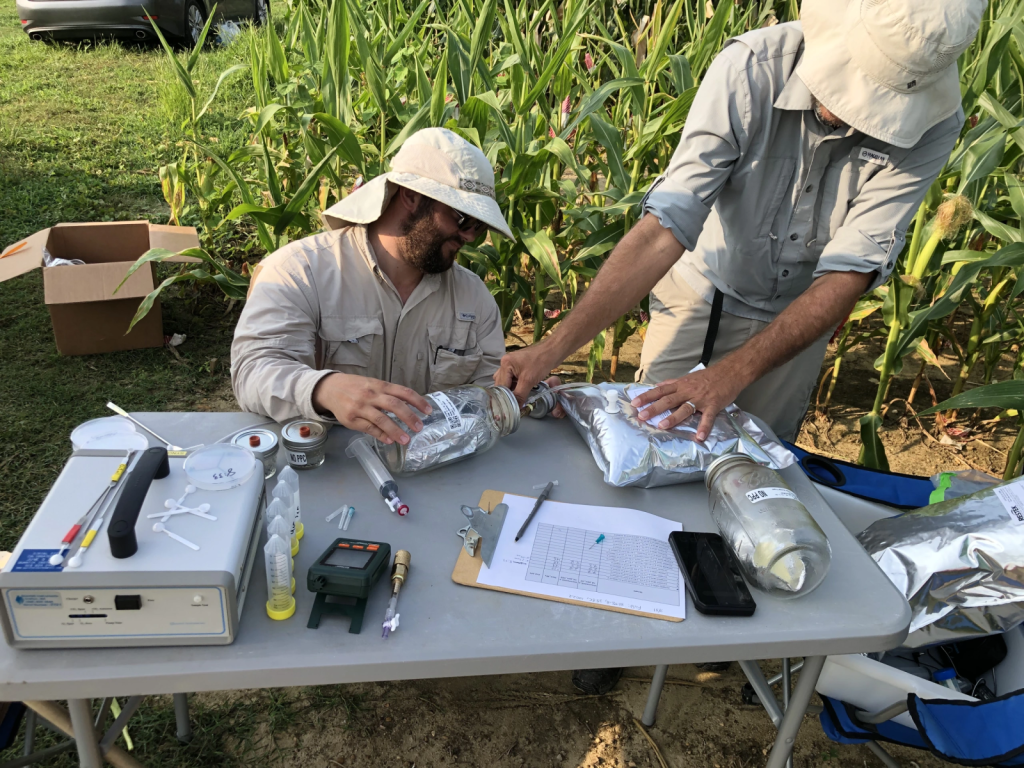

A key milestone: Jared Carter collecting a liter of pollen in the field.

A key milestone: Jared Carter collecting a liter of pollen in the field.

But storage is only half the battle. For effective pollination, stored pollen needs a carrier material that prevents clumping while allowing pollen to bind with plant silks.

The industry standards — talcum powder and amorphous silicas — prevented clumping but excessively coated pollen grains, reducing successful pollination rates. The team initially found success with crystalline silica but had concerns about respiratory hazards and global availability.

The team’s solution? Microcrystalline Cellulose (MCC), a refined wood pulp that looks like a fine white powder. “It’s sustainable, biodegradable, and much safer than silica,” explains Carter. MCC doesn’t coat pollen in the same way and still manages to keep the pollen molecules from clumping together.

A key milestone: Jared Carter collecting a liter of pollen in the field.

A key milestone: Jared Carter collecting a liter of pollen in the field.

This breakthrough exemplifies Syngenta’s core approach: bold discovery leading to better benefits at bigger scale. This kind of accessible science is essential to develop higher yielding hybrid corn in a more sustainable way. As climate challenges mount and food security concerns grow, innovations like this demonstrate how Syngenta empowers farmers to meet the dual challenge of producing more food while preserving our planet.

“What’s most exciting about this new protocol is its scalability and its simplicity,” Carter says. “We’ve tested this across the world, and we’ve found it works with tropical and temperate corn, using equipment that’s easy to get in the field and pollen stored with our protocol can achieve equivalent results to fresh pollen too.”

The next challenge for this breakthrough is to scale things even further but Carter is excited about what he and the wider team have managed to solve.

“This was the result of an amazing team of people from across the world working together in the field. Now we’ve developed this protocol, we’ve got so many exciting possibilities on the horizon.”